nitrocellulose

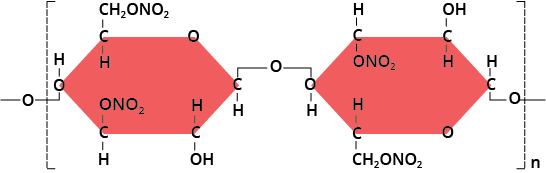

Nitrocellulose is the commercial term for cellulose nitrate, the nitric ester of cellulose. It is obtained by esterification of cellulose and nitric acid.

The degree of esterification—the number of nitrate groups per glucose unit—is characterized by the nitrogen content, and can be influenced by the composition or the concentration of the nitrating acid. NC with a nitrogen content of 10.7–12.2% is typically used in the production of inks and lacquers; NC with 12.6–13.4% nitrogen content is used in energetic formulations such as propellants and dynamite.

IPI provides nitrocellulose for use in propellants and dynamite.

- Wetted with 27–30% water

- Nitrogen content: 13.6% max

- CAS No. 9004-70-0

- UN No. 2555

- MIL-DTL-244B

NITROCELLULOSE SPECIFICATIONS:

| Properties | Units | Values | Test Method | |

| Min | Max | |||

| Material | Manufactured from cotton cellulose meeting the requirements of MIL-C-206 | 3.2.3 and MIL-C- 206 | ||

| Water Content | % | 27.0 | 30.0 | |

| Nitrogen content | % | 13.10 | 13.20 | MIL-STD- 286, method 209.3 or 209.11 |

| Acetone insoluble | % | – | 0.2 | 4.5.3 |

| Ash | % | – | 0.4 | 4.5.4 |

| Viscosity | seconds | 9 | 15 | 4.5.5 |

| Fineness* | ml | 70 | 80 | 4.5.6 |

| Methyl Violet Heat Test (134.5ºC) | minutes | 30 | – | 4.5.8 |

| Workmanship | Uniform composition, texture, and color for Class 2 grade C | 4.4 and 4.5 | ||

* Value of fineness is determined from NC (water wetted) before the process of wetting with alcohol

Water used in manufacturing shall be clean and free from suspended matter or sediment.

NC grade C, Type I may be manufactured from a blend of:

- Grade A Type II 12.6% ± 0.15% nitrogen, and

- Grade B 13.21-13.40% min